Explore our products

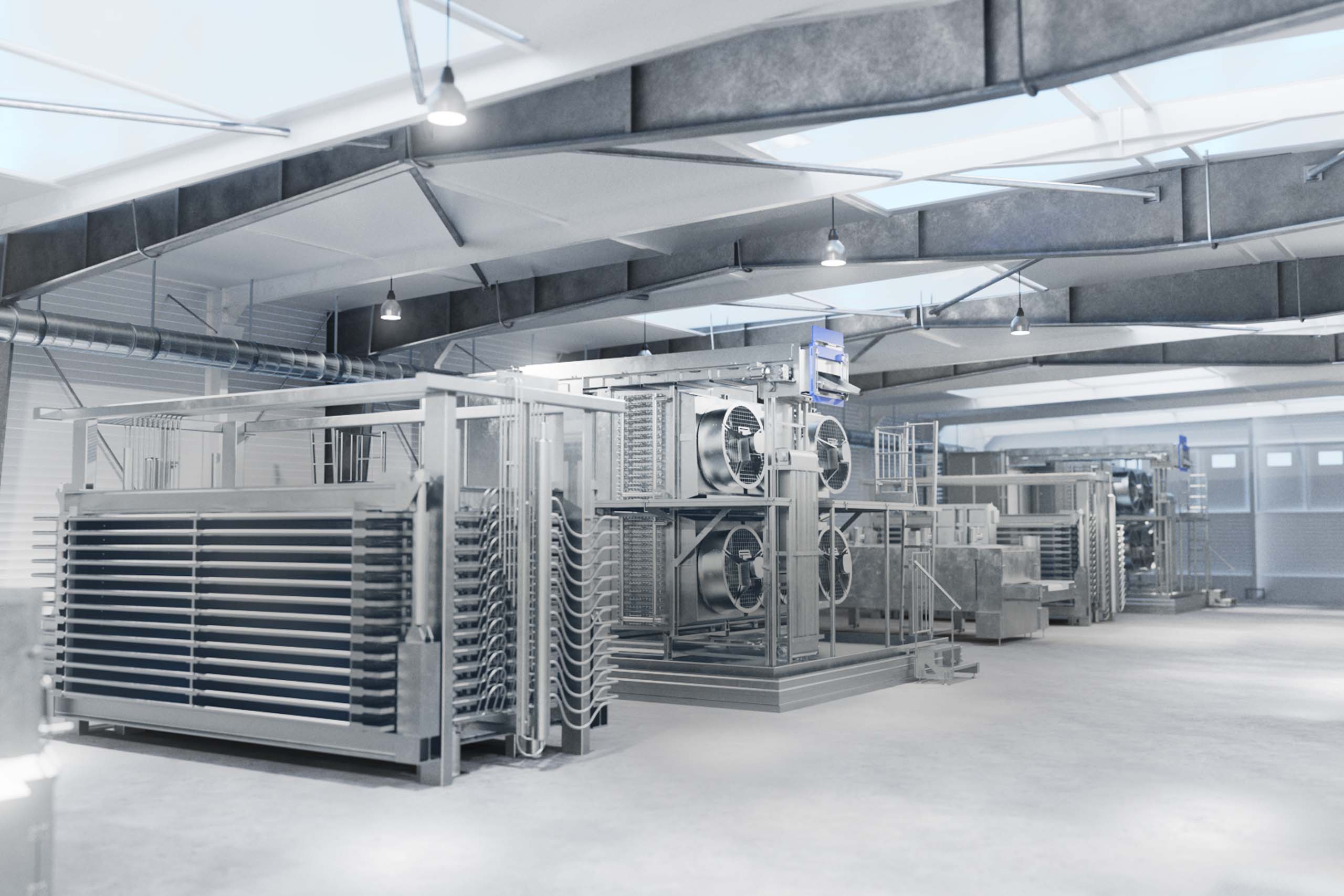

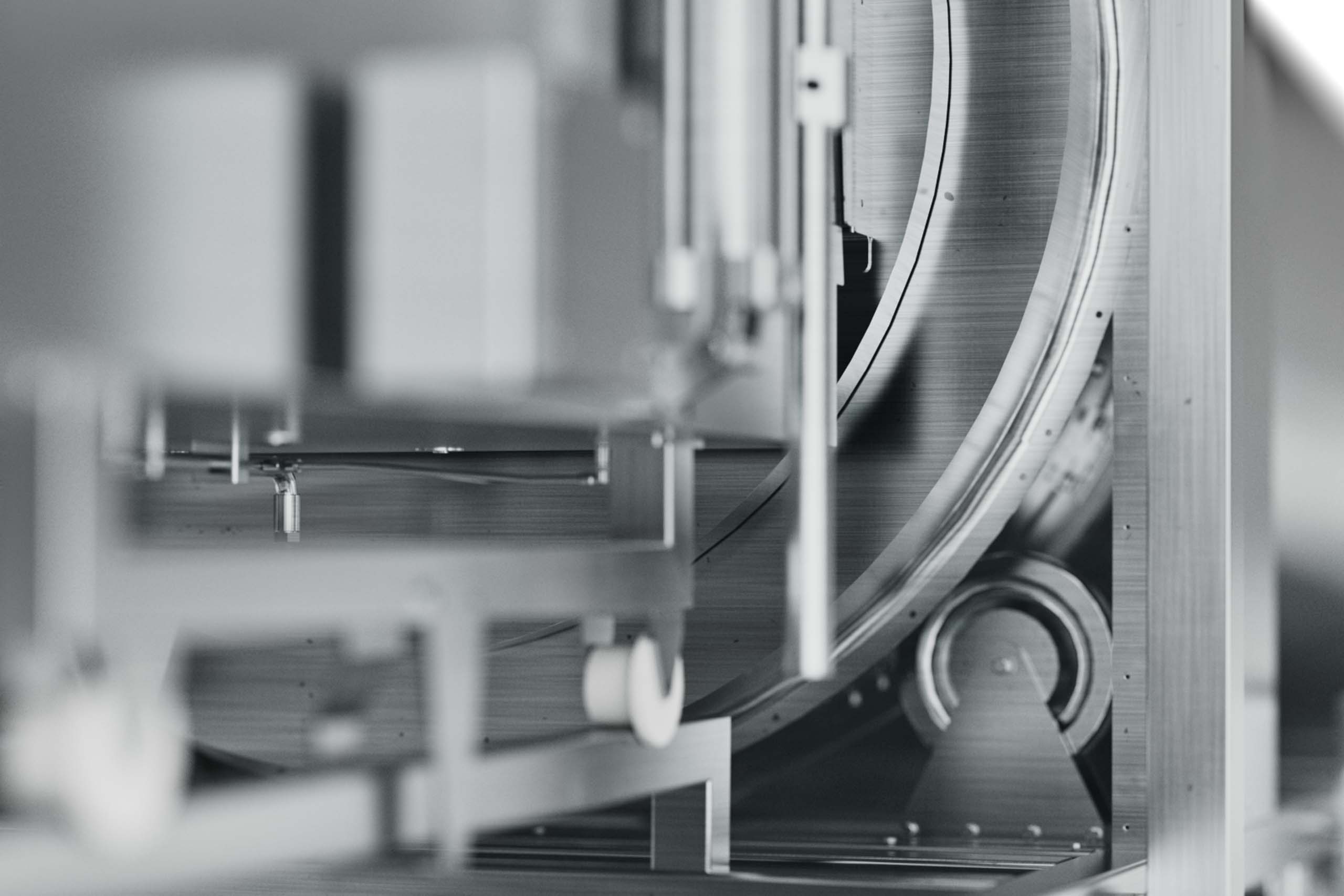

IQF mechanical spiral equipment

Spiral IQF solutions are designed to minimize the cost per kg treated product, ensure a low energy consumption, and guarantee the maximum yield.

Read more

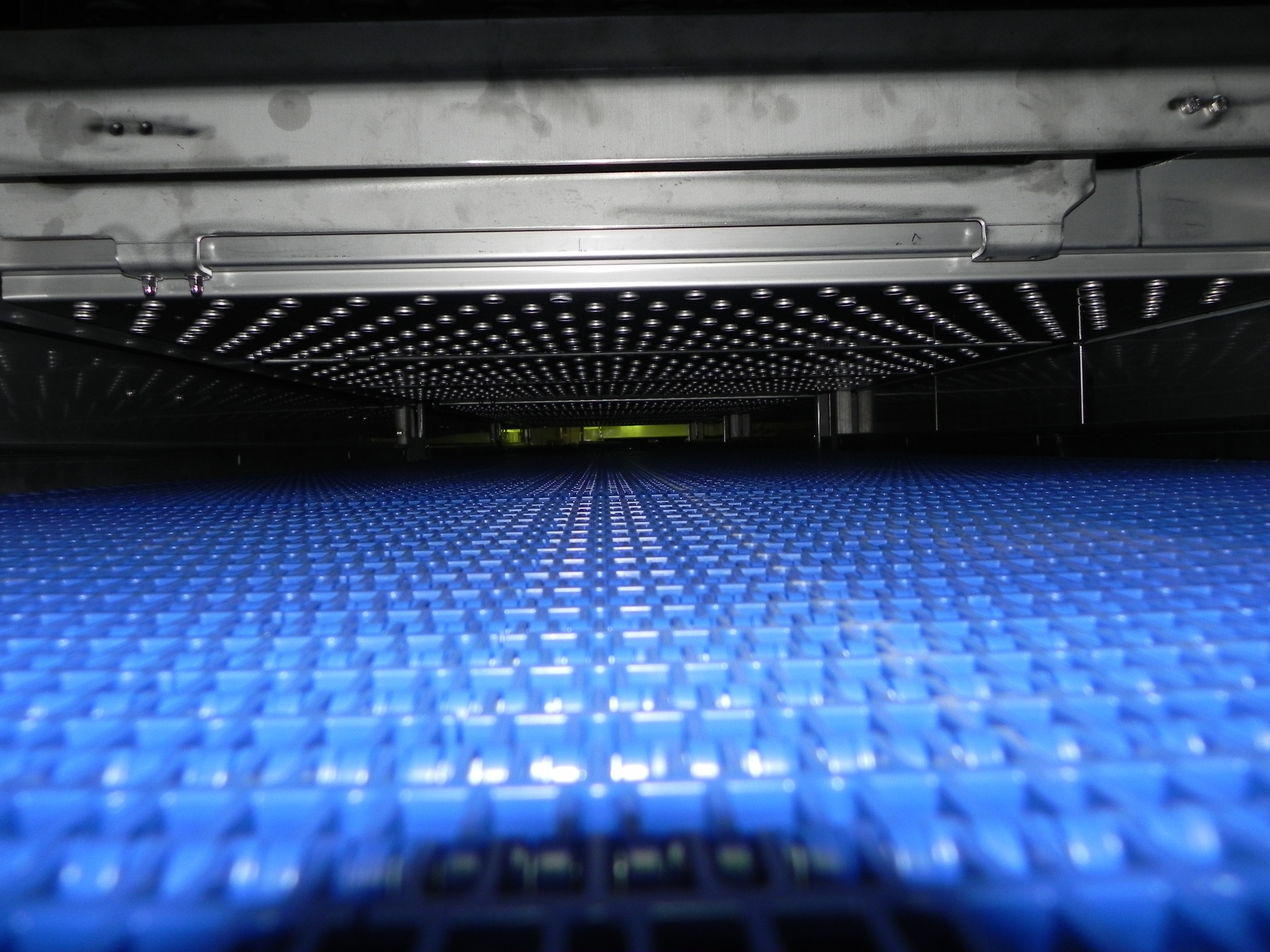

IQF tunnel freezers and cookers

IQF tunnel systems are ideal for freezing, cooling, and heating quality food. This is a method to preserve the freshness and natural appearance of your frozen food while increasing your profitability.

Read more

Vertical plate freezers

Vertical plate freezers are ideal for freezing large volumes of food and liquids very quickly to sustain the food quality and ensure food safety.

Read more

Horizontal plate freezer

Horizontal plate freezers are ideal for freezing products in trays, cartons, boxes, or frames. The technology is based on direct and double contact freezing. This results in fast freezing with high product quality and yield.

Read more

IQF cryogenic spiral equipment

IQF cryogenic spiral solutions are ideal for large volume freezing and chilling of a very wide range of food such as meat & poultry, fish, baked goods, dairy products, and ready meals. It is also a good match for food with a long residence time or productions with minimal available floor space.

Read more

IQF cryogenic tunnel equipment

Cryogenic tunnel cooling, chilling, and freezing are ideal for continuous food processing. The method is used in a wide range of industries, from bakeries to manufactures of fish, poultry, and red meat as well as fruit & vegetable producers.

Read more

IQF cryogenic batch equipment

Cryogenic batch equipment is ideal for food and metal treatment.

Read more

IQF cryogenic tumbler equipment

Cryogenic tumbling is especially suitable for freezing or chilling of small bulk products.

Read more

Reconditioned equipment

Our thermal treatment equipment run for years. Sometimes it even outruns the original production needs. In that case, we repair and service the machinery to put it back on the market.

Read more